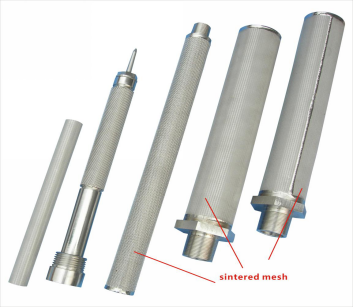

Contrast between the sintered filter element and pleated filter element

The comparison of the two filters:

Name | Pleated mesh filter | Sintered mesh filter | |

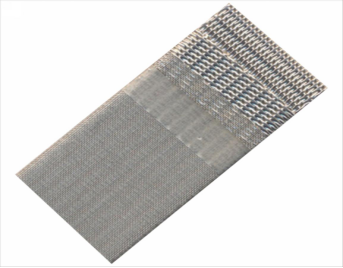

Raw Material | Stand 3-layer mesh | Standard 5-layer sintered mesh | |

Micron rate | 1um-300um | ||

Process | Pleat(pleated is to fold the mesh into corrugated, increase the filter area.) | Sinter (sintering is a process that improves the characteristics of wire mesh by bonding the contact points of all the wires together to form a new product) | |

Standard thickness | According the mesh | 1.7mm | |

Working pressure | According to the perforated tube | About 6 bar | |

Temperature | 450℃ | 600℃ | |

Advantage | Large filtration are (5-10times) as normal cartridge shape filter cartridge | Cleaning is more convenient, long service life. | |

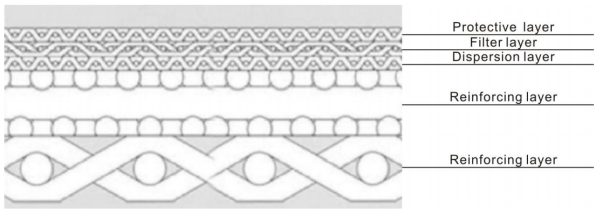

Standard sintered five-layer mesh consists of the protective layer, the filter layer, the dispersion layer, and two reinforcing layers. It provides excellent performance such as uniform and stable precision and high strength

Standard 5-layer mesh structure:

Notice:

According to your requirement, pls check the following info:

Micron rate is 1um, if the OD is 60mm, length is 30”,

The flow rate of each pleated filter cartridge is about 1.7m3/h

The flow rate of each sintered filter cartridge is about 0.4m3/h

Pay attention to qr code

Get the latest information